Project Rapid: 3D printing the harnessing model

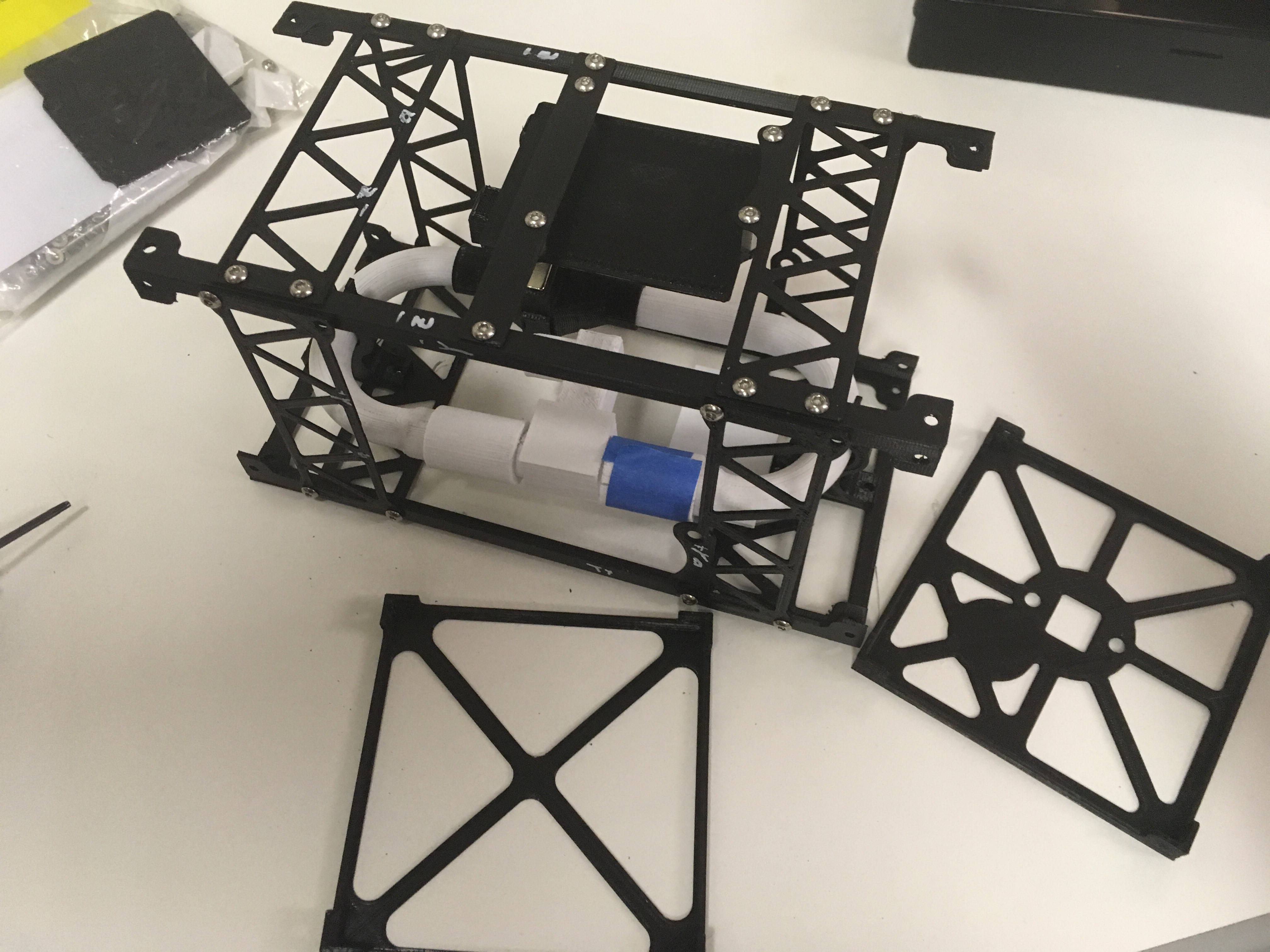

These past few quarters, I’ve been working on structures for Project Rapid’s Blue Dawn mission, a magnetohydrodynamic pump in a 2U CubeSat form factor that’ll hitch a ride on a Blue Origin rocket later this year. In order to assist the electronics team, we’ve 3D printed a harnessing model—it’s so small!

Chassis (PLA).

Chassis, with payload: MHD pump (black, assembled with magnets, in rear), flowmeter model (in white).

During the 3D printing process, one of the issues that’s come up is the inability of 3D printers to make round shapes, making tubes/pipes difficult to mate. Cylinders get printed with one side more elliptical/angular than the other. Sounds obvious, right? 3D printers can’t make infinitely thin lines! I’ll need to play with slicing settings in Cura to see whether decreasing layer height, using rafts, or modifying support geometry might help.

Cylinder orientation print test: two variations. Note the “nubs” on the lower halves of the cylinders to the left.

Cylinder orientation print test: two variations. Note the “nubs” on the lower halves of the cylinders to the left.