TPU, TPMe

“I shall call him Squishy and he shall be mine and he shall be my Squishy.” -Dory, Finding Nemo (2003)

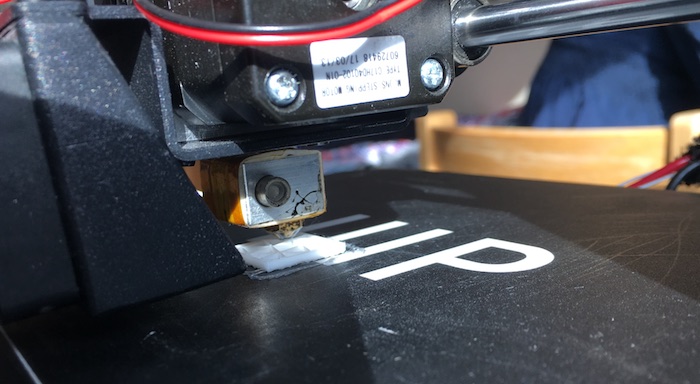

After purchasing flexible filament back in SEPTEMBER for my rollerblade wheels, I finally got a chance to print it! It’s only a calibration cube so far, but I like how there’s two different directions of squishiness: the cube is more resistant in the z-direction, since the infill is built up in that direction; however, it’s significantly more flexible in the x- and y-directions.

Unfortunately, with 20% infill, my enthusiastic squishing in the y-direction caused mild delamination within a few hours. (This fracture also may suggest that rollerblade wheels need to be printed in an upright configuration, such that the weight is applied in the same direction as the infill.)

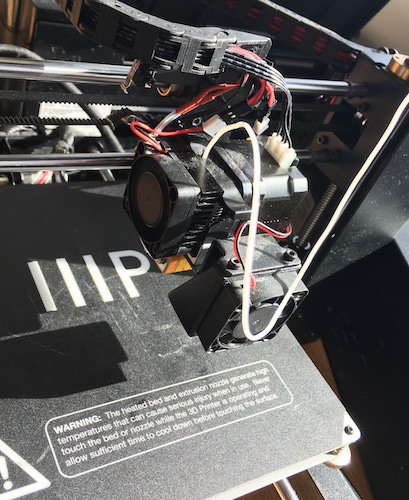

In order to print TPU, I had to unscrew the cooling fan and manually feed the filament into the Bowden extruder due to the plastic’s flexibility and tendency to buckle.

The filament has a tendency to “flop” when released.

Surprisingly, I didn’t have to print any mods, or even install a PTFE tube; however, if I want to print faster than 10 mm/s, that may be necessary.

Initial layers: there were no issues with bed adhesion. In fact, for some print bed surfaces, it’s recommended to use tape for easier part removal.